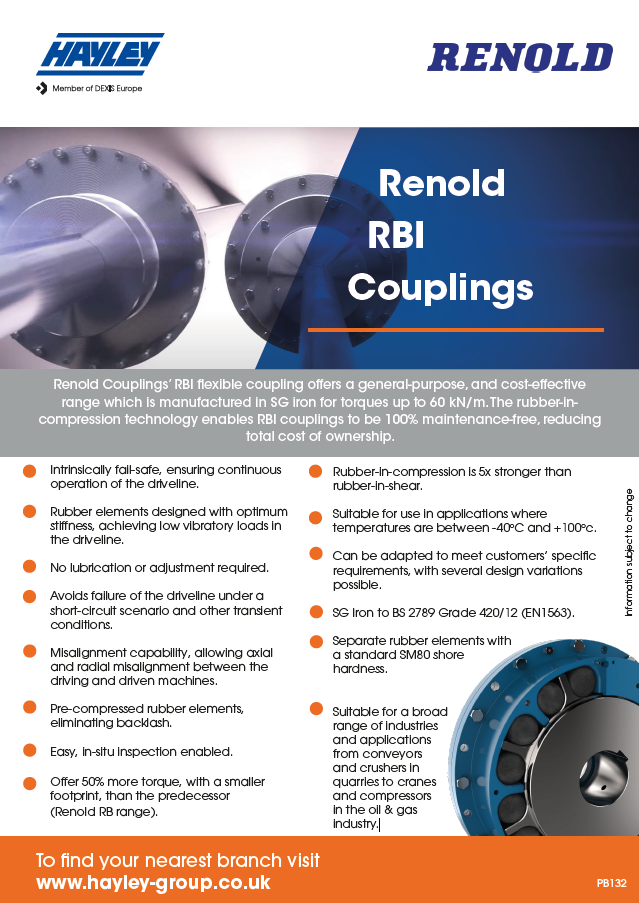

Renold Couplings’ RBI flexible coupling offers a general-purpose, and cost-effective range which is manufactured in SG iron for torques up to 60 kN/m. The rubber-in-compression technology enables RBI couplings to be 100% maintenance-free, reducing total cost of ownership.

- Intrinsically fail-safe, ensuring continuous operation of the driveline.

- Rubber elements designed with optimum stiffness, achieving low vibratory loads in the driveline.

- No lubrication or adjustment required.

- Avoids failure of the driveline under a short-circuit scenario and other transient conditions.

- Misalignment capability, allowing axial and radial misalignment between the driving and driven machines.

- Pre-compressed rubber elements, eliminating backlash.

- Easy, in-situ inspection enabled.

- Offer 50% more torque, with a smaller footprint, than the predecessor (Renold RB range).

- Rubber-in-compression is 5x stronger than rubber-in-shear.

- Suitable for use in applications where temperatures are between -40ºC and +100ºc.

- Can be adapted to meet customers’ specific requirements, with several design variations possible.

- SG Iron to BS 2789 Grade 420/12 (EN1563).

- Separate rubber elements with a standard SM80 shore hardness.

- Suitable for a broad range of industries

and applications from conveyors and crushers in quarries to cranes and compressors in the oil & gas industry.

Enquire about RBI couplings from Renold by speaking to the team at your local Hayley Group branch. Find their details by using our Branch Finder tool.