Mechanical Engineering Services

24/7/365 non-stop engineering excellence

We can provide a comprehensive range of predictive, reactive, and planned mechanical engineering services to a broad range of industry sectors, including automotive, utilities, food & beverages, and aggregates.

Our team of highly regarded and experienced engineers, working with cutting-edge equipment, are capable of delivering a range of mechanical engineering services including gearbox refurbishment and overhaul, pump services, machining and fabrication and electric motor repairs and rewind.:

Working with you to...

Maintain operations

Reduce lifecycle costs

Strive for efficiencies

Achieve asset performance improvements

Our Facilities

We continue to invest heavily in our people, equipment, and technology, to stay ahead of the game. We are located in a modern 35,000 sq. ft. engineering facility in Dudley, West Midlands; with a state-of-the-art satellite facility in King's Lynn, Norfolk.

Inhouse machine shop

Inhouse fabrication facility

Inhouse pump performance testing

Approved Belzona coating facility

Inhouse electric motor rewind facility

Gearbox Refurbishment and overhaul

We are accredited by SKF as a Certified Gearbox Rebuilder, becoming the very first company in the UK to be granted this accolade.

We specialise in the refurbishment and emergency repair of all types of industrial gearboxes. Ranging from large custom-built crane gearboxes, pulverising mill gearboxes and extruders, to smaller catalogued gearboxes and geared motors.

- Same day collection, strip down and reporting

- Detailed inspection report and rebuild quote

- Up to 50 tonnes capacity

- Washdown and steam clean facility

- Fully-equipped spray booth

- Testbed facility

- 300 tonnes horizontal and 150 tonnes vertical press capacity

- Full process and quality control documentation for all repairs

- On-site support available for inspection, plant removal, and installation work

- Permanent night shift engineers for full 24h coverage

- Call-out system in place to enable rapid breakdown service

- Supply of OEM parts

- Re-engineering of obsolete components

- OEM warranty

- Root cause failure analysis

- Oil analysis service

- Vibration analysis service

- Asset management

Helical speed increasers

Single & double reduction worm reducers

Helical & helical bevel reducers

Geared motors

Shaft-mounted reducers

Variators

Epicyclic & planetary units

Pump Services

We specialise in all pump repairs and refurbishments from a basic pump repair right through to a complete pump turnkey project, including full energy efficiency up-grade and refurbishment in accordance with the WIMES specification. We also have the capability to design and manufacture pump baseplates, pipework, and protective coatings all in-house to support our site removal, installation, commissioning, and pump performance testing services.

- 2x 7000L test tanks for wet-end and submersible pumps

- Capable of 650m3/h @ 110m for end-suction, split-case, and multi-stage pump sets

- Capable of Factory Acceptance Testing (FAT) on new assets

- Optional live video stream of testing available to customers

Belzona-approved coating centre:

Work is carried out in a specially designed and controlled environment for the application of Belzona WRAS Approved efficiency, abrasion, and chemical-resistant coatings. All coatings are applied in accordance with the relevant ISO Standard ISO 5802.

Dynamic balancing:

We are always looking at increasing our customer’s asset performance and increase MTBR and an important part of that process is the dynamic balancing of all of the rotating elements of a pumping asset.

- Rotating elements up to 3000kg

- Maximum distance of 2.5m between bearing centres

End-suction pumps

Multi-stage pumps

Boiler-feed pumps

Split-case pumps

Wet-end pumps

Submersible pumps

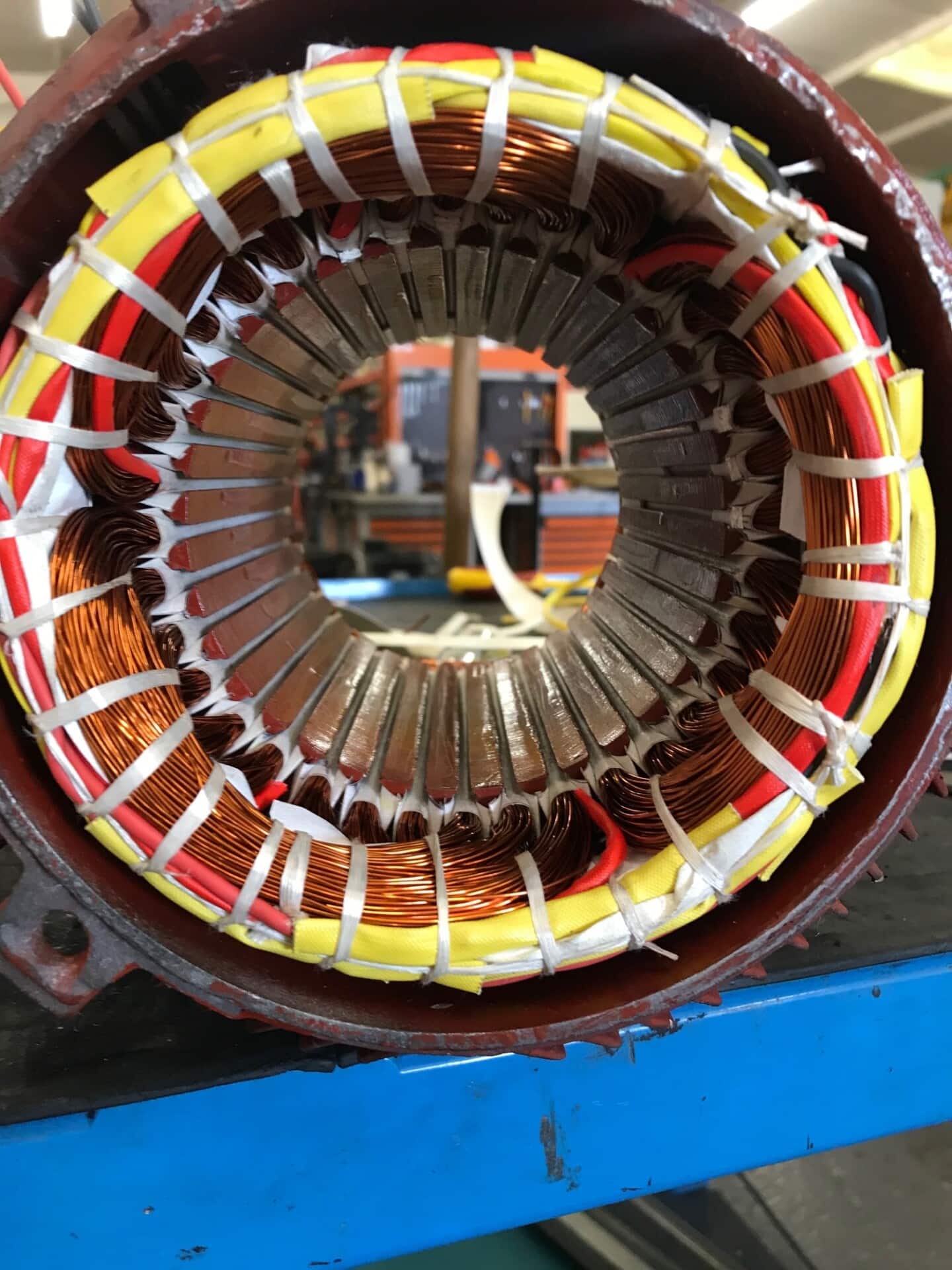

Electric Motor Repairs and rewinds

We specialise in the repair of electrical motors from a wide variety of manufacture and can repair all types and sizes , ensuring the repair is carried out to a high standard to maintain the units efficiency.

Our capabilities over two sites:

- AC/DC motor repairs on and up to 50 tonnes

- AC/DC motor - pumps - geared unit - fans - coil rewinds - servos

- Atex-rated equipment repairs and rewinds

Extended capabilities:

- Collection and delivery service

- Experienced team to help with on-site fault-finding

- Removal, installation, and bearing changes available as on site services

- Detailed reporting incl. photographic evidence of repair requirements prior to commencement

- All repairs fully-stripped, winding is tested using specialist equipment

- All motors rewound with class F/H specification material

- New state-of-the-art burn-out oven used to remove old windings

- All units returned with a test certificate and protective wrapping

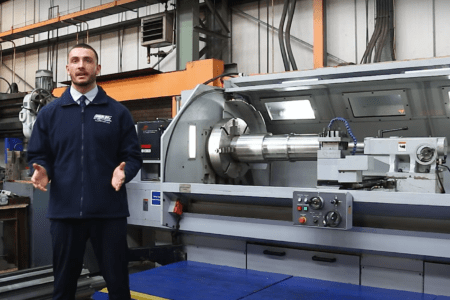

Machine Shop Services

We specialise in reactive, reclamation, and refurbishment work, including reverse engineering. Our state-of-the-art machining facility can accommodate a comprehensive range of small to large, heavy components with a capacity of 12 tonnes for single components.

Using the latest CAD/ CAM software we are able to offer drawing and design services. Using the CAM Software we can programme offline and send it directly to the machine tool. This has its advantages by increasing efficiency with tool paths and working in conjunction with tool changes.

Our technical, skilled, and committed team of machinists boast a wealth of experience from various industry sectors working under tight tolerances and in the most demanding environments.

Additional services include:

- Normalising

- Stress relieving

- Heat treatment

- Grinding

- Electrical discharge machining (wire & spark)

- Metal spraying & specialist coatings

- Priming & painting

- Powder-coating

- Plating

- Galvanising

- Anodising

- Load-testing & NDT-testing

- Available 24/7/365

Machining & Fabrication

We specialise in reactive, reclamation and refurbishment work, including reverse engineering. Our dedicated fabrication facility offers a comprehensive range of small to large, heavy fabrications with a capacity of 5 tonnes for single components, and 50 tonnes for full assemblies.

Our welders are coded and offer TIG, MIG, and MMA welding processes working in accordance with weld procedures across a variety of materials such as; aluminium, inconel, mild steel, and stainless steel.

Additional services include:

- Machining

- Stress relieving

- Soda or abrasive blasting

- Priming and painting

- Powder-coating

- Plating

- Galvanising

- Anodising

- Load-testing & NDT-testing

- Installation services

Relevant Content

Downloadable Content

To download content, click the front cover of your chosen brochure/catalogue below.