Clive Jennings, Cooper Bearings Product Manager - SKF

The advantages of split bearings – including faster replacement and reliable sealing – make them ideal in demanding applications, says Clive Jennings, Product Manager for Cooper split bearings at SKF.

Working conditions in industries such as steel, cement, mining and mineral production can be tough. Excess dust and heat – or the risk of flooding – can put both bearings and staff under pressure. To cope with the rigours of aggressive environments experienced in heavy industries such as these, split bearings have typically been the obvious choice. However, their ease of installation – and effective sealing performance – is now seeing them used increasingly in other industries.

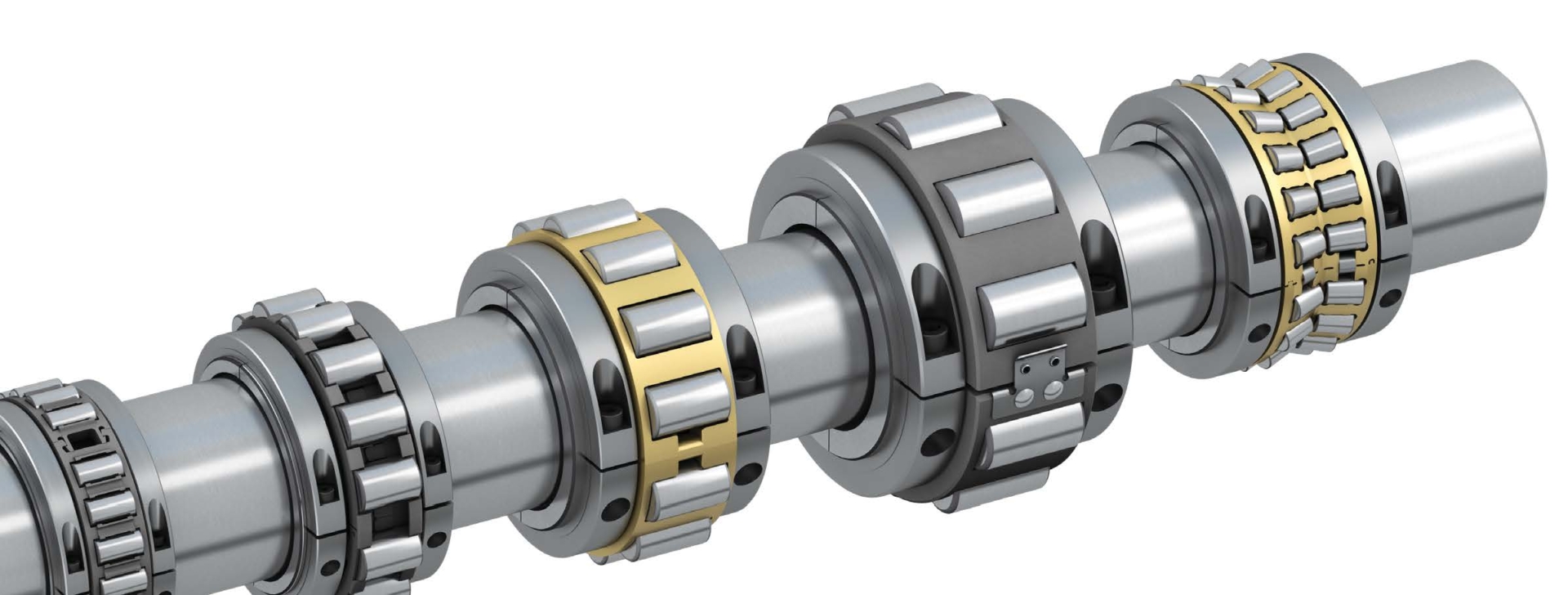

In many cases, SKF’s Cooper split bearings are an ideal solution. Unlike solid bearings – which must be slid onto a shaft – Cooper bearings split to the shaft, making them quick and easy to install. This is particularly true when a bearing sits between two pieces of equipment such as a gearbox and a motor. (This is known as a ‘trapped’ application.)

It might take two people many hours to change a solid bearing in this type of application arrangement. With a split bearing, one person could do the same job much quicker. In extreme cases, it can be necessary to break and replace a piece of expensive equipment in order to remove a faulty solid bearing and fitting a replacement is equally challenging and expensive.

This can be resolved by using a split bearing. Ease of installation is the main reason split bearings are increasingly being specified. The time saved varies according to the application but can be substantial: mean time to repair (MTTR) is typically reduced by 70%, which minimises downtime.

Another huge benefit is their contribution to workplace safety. Split bearings can be replaced in-situ, which simplifies maintenance and repair. This is critical in applications such as conveyors. Here, an estimated 43% of all accidents – and 24% of fatalities – occur during maintenance.

Anything that increases machine reliability – and lessens worker exposure to hazardous conditions – can help to reduce these numbers. This is especially true in industries such as cement and mineral processing – where the conditions typically cause bearings to fail more quickly.

Traditionally, SKF’s Cooper split bearings were used in heavy industries such as mining and steelmaking. However, development of solutions in these sectors in the UK has seen split bearings finding use in a range of other areas – such as water treatment.

As well as being a stable industry, the water sector is characterised by many small, automated sites. However, the many advantages of SKF’s Cooper split bearings – from effective sealing to fast, easy installation – has seen them specified more frequently.

Split bearings are routinely used in water treatment units including filter beds, sludge and waste conveyors, flocculators, aerators, pumps and pumping stations. In each case, they can reduce maintenance time and increase productivity – by cutting inspection and maintenance to a minimum. In addition, split bearings handle shaft misalignment in a unique way, so can maintain effective sealing – another persuasive argument for their use in this sector.

Aside from the water industry, split bearings can be applied to two main types of machinery: conveyors and industrial fans. These are found in a wide variety of locations – including production facilities, hospitals and paint shops. These applications typically use the solid bearings that were installed by the OEM.

Retrofitting a split bearing can save the machine operator money in the long run, by reducing maintenance time. And, while customers can be reluctant to switch to split bearings, there are many detailed examples of customers that have benefited from doing this. Split bearings can be applied to many applications, but their use is not always obvious. This is where Hayley’s staff can help customers identify applications that might benefit from this kind of retrofit.

Split bearings are also available as bespoke products. And we have a dedicated application team in the UK available to collaborate with Hayley’s teams and customers to find the best solution that maximises asset availability.

SKF recently further developed its offerings of split bearings, with the introduction of its E-series. These have a unique, patented brass cage design – which increases carrying capacity and rating life. Typical applications include belt and screw conveyors, industrial fans, propeller shafts and water turbines.

Split bearings reduce maintenance bills and total cost of ownership while simultaneously improving worker safety. Want to find out more? Speak to your local Hayley Group branch. Find their details by using our Branch Finder tool.

This article features in Issue 6 of our First For Bearings magazine. Find a digital copy of all back issues of this magazine by clicking the button below: