By Richard Robson, Regional Sales Engineer - NSK Europe

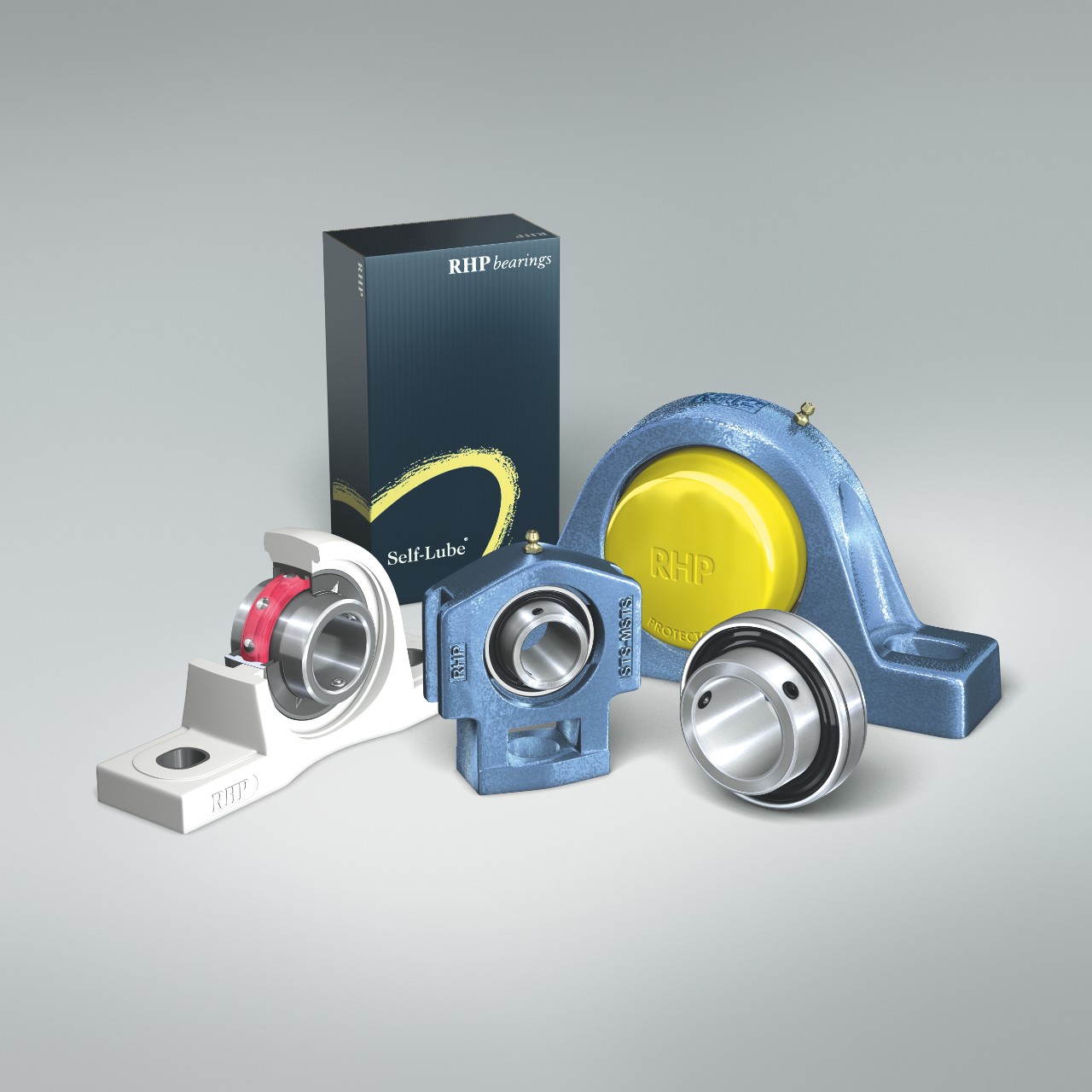

NSK’s Self-Lube® housed bearing unit is the

recognised industry standard for high quality mounted units. The unit was originally an innovation of RHP, Britain’s largest bearing manufacturer, which was acquired by NSK in 1990. Today, we still make these products at our manufacturing plant in Newark, Nottinghamshire and they continue to represent an important part of the NSK portfolio available from Hayley.

The popularity of RHP Self-Lube® housed bearings endures for many reasons, not least because they help OEM manufacturers and end users to improve their competitiveness, cutting build and maintenance times by reducing bearing complexity and mounting costs. Without mounted units, you would have to construct your own bearing housings for attachment to your machines, and find a way to lock the bearing on to the shaft.

Self-Lube® housed bearings save the time and cost of this activity with an off-the-shelf solution based on a pillow block, flange unit, take-up unit, cartridge unit or hanger unit to suit the application. Easy machine attachment and shaft locking via a set screw on the inner ring make for easy installation.

For this reason, Self-Lube® bearing units are found across industry, from conveying and automated equipment at quarries, airports and food plants, through to agricultural farming implements. As the UK market leader for a generation, the RHP Self-Lube® range has benefited from continuous development and innovation, providing you with quality, longevity and ease of use. For example, our Self-Lube® units can accommodate moderate misalignment and be adapted to a huge number of applications. Working in close liaison with Hayley, we’ve seen the success of Self Lube® in sectors that extend from steelmaking and general manufacturing, through to food processing, materials handling, cement, packaging, paper, print and textiles, to list but a few.

As an alternative to standard Self-Lube® cast iron housings, machine builders serving the UK’s biggest industry sector, food, can take advantage of materials such as corrosion-resistant, high-quality stainless steel or thermoplastic designed in such a way to avoid RHP Self-Lube® range of harbouring bacteria.

As well as the housing, Self-Lube® units comprise a bearing insert. Each insert is essentially a high quality deep-groove ball bearing, made to our popular 6200 series configuration, with integral design features making it more functional and versatile than a standard ball bearing. HLT Inserts are also available to help reduce maintenance, downtime and replacement costs when operating at extreme temperatures from -40 to +180°C.

Our Self-Lube® bearings are factory charged with the correct amount of grease. You won’t normally need to perform re lubrication, except when operating at extremes of temperature, speed or loading, or where excessive wet or dirty conditions are prevalent. Three sealing arrangements are available. The standard S-type seal consists of a nitrile rubber sealing element bonded to a strong steel former. Where extra protection is required without loss of speed, the ‘flinger seal’ is ideal, consisting of a steel flange adhered to a flexible nitrile sealing lip. For applications with a high degree of contamination, the specially developed triple lip seal becomes first choice. It consists of a one-piece moulded nitrile seal with three sealing lips, bonded to a protective steel outer pressing secured in the outer ring.

Similarly, you can select from a trio of shaft locking arrangements. The standard set screw consists of two knurled cup-point, self-locking, sockethead set screws fitted in the extended inner ring. For demanding applications, we also offer taper sleeve lock and eccentric collar lock options. The latter consists of an eccentric diameter formed on the extended inner ring of the bearing that engages a similarly formed eccentric diameter in the bore of a separate collar. Locking occurs by turning the collar in the direction of shaft rotation. In all cases, our partnership with Hayley means you’ll always have access to decades of experience and know-how, ensuring the optimal configuration of your Self-Lube® bearing units.

As a point of note, we also manufacture associated ranges which include Silver-Lube®, a corrosion-resistant version of Self-Lube® that uses high-grade stainless steel bearing rings, cage, balls and other components. Also available is the NSK Life Lube® series, which combines the corrosion-resistant properties of Silver-Lube® housings with the excellent sealing and lubricating properties of NSK’s Molded Oil inserts. Life-Lube® units are specifically for use in industries where contact with water and process fluids is unavoidable and longer lubrication life is necessary.

To enquire about RHP Self-Lube and Silver-Lube products from NSK, speak to a member of your local Hayley Group team. Find all of their details by using our Branch Finder tool.